Smart, Efficient, High-Flow Compression Powered by Hanwha Engineering

Powerful, efficient, and built for nonstop industrial performance—Hanwha compressors bring together advanced engineering and intelligent controls to deliver dependable air power at scale. From high-volume manufacturing to heavy industrial applications, the SM and SA Series offer impressive capacity ranges and long-term cost efficiency. Blake & Pendleton partners with you to design and support a Hanwha system that improves reliability, reduces energy consumption, and keeps your plant moving forward.

Customer-tailored High-performance, High-reliability Turbo Compressors

- Achieving high efficiency and energy savings through proprietary designs and technologies

- Compliant with various international standards including API, ASME, PED, KOSHA

- Providing 100% Oil Free solutions(ISO8573-1 Class 0)

- Simple structure offering easy installation/maintenance

- Customized solutions including complete compressed air systems per specific user requirements

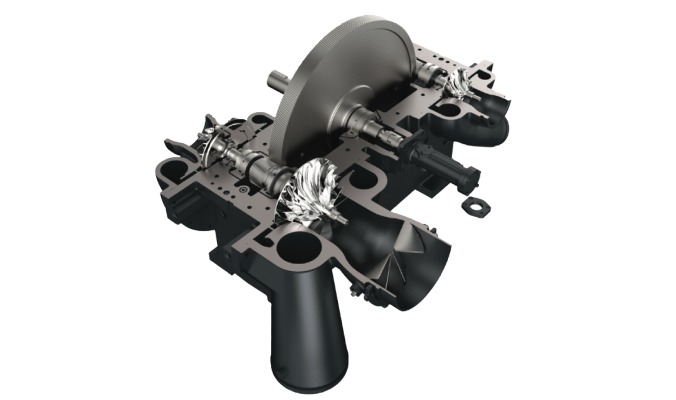

High-durability gear system based on cutting-edge technology

- Delivering peak performance based on over 30 years of accumulated design expertise

- High reliability and durability proven through numerous operational experiences

- Reduced maintenance time through simple field disassembly

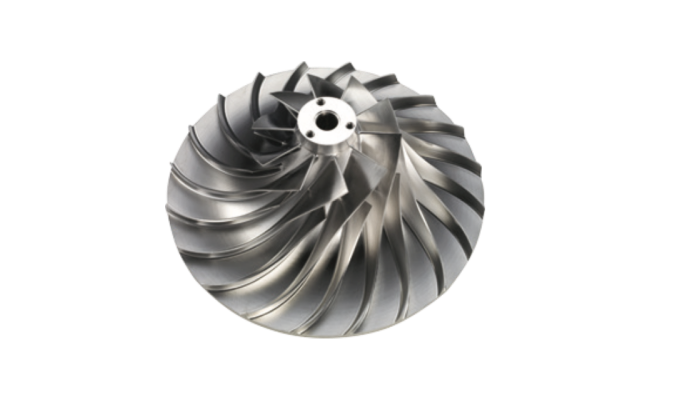

Impellers manufactured based on proprietary/advanced design technology

- Maximizing optimal stability and energy efficiency through precise design

- Securing high reliability through low vibration and low noise achievement

- Implementing optimized customer-specific designs

Inlet Guide Vane for energy savings

- Optimal design and arrangement for improved efficiency

- Precise flow and pressure control capability

- Power consumption reduction through partial load adjustment

High-durability Coolers

- Optimal Airflow design minimizing Pressure Drop

- Superior durability through materials suited to user environments

- Easy cleaning and maintenance with straight water-in-tube type

AirLogix® is an advanced control solution for centrifugal air compressors. Built on the Allen-Bradley family of PLCs we’ve developed a solution that delivers unmatched results. AirLogix® optimizes energy efficiency, increases reliability, and promotes system visibility through data and integration. Each controller we build is custom, engineered specifically for each application, and done with nearly unlimited capabilities.

What sets AirLogix® apart from any other controller is our unique control algorithms and methodology. Through decades of experience, we’ve developed a product that completely automates and optimizes the compressor. To achieve this, we continuously monitor and adjust for real-time major influences on performance like changes in ambient air temperature, pressure, and various rate-of-change functions.

AirLogix® is incredibly user-friendly but also open-source which means it consists of no Case Controls proprietary hardware. The HMI home screen provides an easy to understand, detailed machine information at a glance. Additional screens provide the ability to create and tailor personalized views to display the information that is of the greatest interest. We give you the tools to add, name, scale, configure I/O, tune PID loops, manual valve control, and so much more.

Unlock the true potential of any centrifugal air compressor with AirLogix®.

High-efficiency Oil-free Air Compressors Proven Across Various Industries

SM3000

| Flow Rate | ㎥/hr | 3,300 ~ 5,300 |

| CFM | 1,950 ~ 3,100 | |

| Power | kW | 210 ~ 680 |

| HP | 280 ~ 910 | |

| Discharge pressure | bar A | 3.5 ~ 18 |

| psi A | 50 ~ 265 |

SM4000

| Flow rate | ㎥/hr | 5,300 ~ 8,400 |

| CFM | 3,100 ~ 4,950 | |

| Power | kW | 310 ~ 1,010 |

| HP | 430 ~ 1,350 | |

| Discharge pressure | bar A | 3.5 ~ 18 |

| psi A | 50 ~ 265 |

SM5000

| Flow rate | ㎥/hr | 8,400 ~ 15,000 |

| CFM | 4,950 ~ 8,850 | |

| Power | kW | 490 ~ 1,540 |

| HP | 660 ~ 1,800 | |

| Discharge pressure | bar A | 3.5 ~ 18 |

| psi A | 50 ~ 265 |

SM6000

| Flow rate | ㎥/hr | 15,000 ~ 21,000 |

| CFM | 8,850 ~ 12,400 | |

| Power | kW | 780 ~ 2,350 |

| HP | 1,050 ~ 3,150 | |

| Discharge pressure | bar A | 3.5 ~ 18 |

| psi A | 50 ~ 265 |