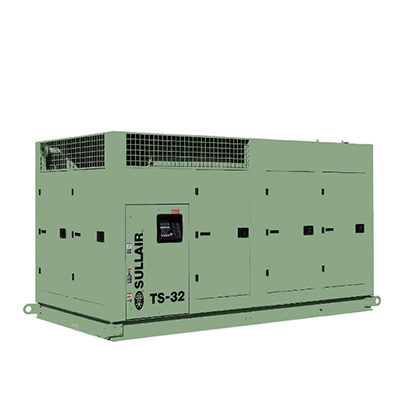

TWO-STAGE INDUSTRIAL (200-600 HP) ROTARY SCREW AIR COMPRESSORS

Sullair Two-Stage compressors feature a superior end-to-end design for optimum efficiency and power savings.

- Longer air end life

- No loss of capacity or efficiency

- Lower operating costs

- 400 – 600 HP, 1681 – 3000 cfm, 100 – 175 psi

- Two-stage technology, High-Performance, Energy-Efficient Design, Superior Longevity Air End Life

- Supervisor Microprocessor Controller

- Legendary Sullair Air End

- 10-Year Air End Warranty

- 5-Year Warranty covering the motor, coolers, and air/fluid vessel

- 10,000-hour Genuine Sullube factory fill lubricant

- Standard Features: TEFC Motors 350HP, ODP Motors 400-600 HP, Heavy Duty Air Filter, TEFC PE Motor, NEMA 4 YD Starter, Phase Monitor, Sequencing, Enclosure, Spiral Valve, Stainless Steel Control Lines and Fittings, Zero Loss Drain

- Options: Variable Speed Drive, 460V or 575V Solid State NEMA 4 Starter, Medium Voltage Motors & Starters, ESS Heat Recovery, Cold Weather Package, Deduct Enclosure, High Static Fan (AC), NEMA 4X Starter enclosure, Pristine Food Grade Lubricant, Weatherhood (AC), Remote Coolers, Air cooled or Water Cooled

Flow

1681 – 3000 cfm

47.6 - 84.9 m³/min

Pressure

100 – 175 psi

7-12 bar

Power

400 – 600 hp

300 – 450 kW

Product Documents

Product Details

-

- Multi-Stage Air-Fluid Separation

- Dual nested Optimizer™ separator elements, reduce fluid carryover to a maximum of 1 ppm

- Reduced carryover lowers make-up fluid costs

- Pleated Optimizer elements lower initial pressure drop for greater efficiency and extends element life

- Easy to change with built-in lid lifting device

- Fiberglass Fluid Filter

- Aircraft-quality media provides better filtration

- Up to 20% more efficient than conventional paper elements

- Lengthens life of the compressor

- Optimalair® Heavy-Duty Air Intake Filter

- Includes remote air intake connection

- Provides finest inlet filtration in the industry (0.4 microns using Fine Fiber Technology)

- Keeps fluid clean and extends life of other internal components

- Reduces pressure drop throughout the operating life, resulting in energy savings

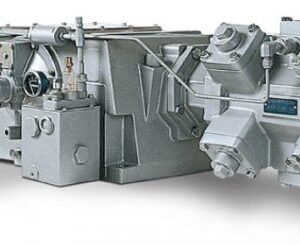

- Two-Stage Compressor Air End

- Delivers more air

- Reduces power consumption

- Extends air end bearing life

- Enhanced Serviceability for Air-Cooled Oil Cooler and Aftercoolers

- Easy to remove panels provide access for cleaning coolers

- Motor Coupled to Air End Through Non-Lubricated, Flexible Coupling

- Allows use of standard NEMA frame motor

- Simplifies installation and start-up

- Variable Capacity Control System Featuring Spiral Valve Technology

- Lowers part-load operating costs

- Reduces cycling duty on package

- Maintains consistent plant pressure

- Simple control

- Reduces bearing load

- Sullair Supervisor™ Controller

- Computer-compatible microprocessor controller has simple graphic illustration of monitored functions and an easy-to-read keypad

- Constant readout of pressure and temperature

- On-demand readout of all operating and maintenance conditions

- Monitors key functions and safety shutdowns

- Power failure auto restart

- Dual control, provides automatic start-stop operation

- Lead-lag and sequencing with multiple compressors

- Service and preventive maintenance schedule

- Hours are recorded for “Run,” “Loaded” and “Consumable Parts”

- Fault history with sensor readings

- “Help” key provides built-in troubleshooting

- Easy Maintenance

- Access to all critical components even with a sound enclosure installed

- Time Proven End-to-End Design

- Reduces pressure drop through stages

- Easy serviceability

- NEMA 4

- Wye Delta starter for softer start

- Bearing Fluid Reservoirs

- Ensure that fluid is available at start-up

- Extend air end life

- Genuine Sullube® Factory Fill

- A 10,000-hour extended-life synthetic fluid powered by Dow technology, Sullube has been used in more than 50,000 compressors worldwide

- Sullair 10-Year Diamond Warranty*

*Maintaining the Sullair 10-Year Diamond Warranty requires using Genuine Sullair parts and fluids, as well as the oil sampling program.

- Multi-Stage Air-Fluid Separation

- Available models60 Hz

- TS-32S-400

- TS-32S-450

- TS-32S-500

- TS-32S-600

- V-320TS-400

- V-320TS-450

50 Hz

- TS-32S-400

- TS-32S-450

- TS-32S-500

- TS-32S-600