Dekker Vacuum Technologies – Vacuum Pumps and Systems

Vacuum is an applications intensive field where products need to be customized for each and every installation. Dekker Vacuum has the knowledge and experience to successfully engineer and apply products to virtually every manufacturing and process segment. On staff are process, chemical, mechanical and electrical engineers whose primary goal is to correctly and accurately place vacuum equipment into demanding production and process applications.

Blake & Pendleton represents Dekker in the southeast USA with a team of industry savvy sales engineers. In addition, our in-house team is comprised of industry leading vacuum experts to ensure vacuum products are properly sized and applied to meet our client’s needs. We routinely perform vacuum system audits to improve vacuum delivery and lower energy and/or maintenance costs. Our extensive field service team supports the installed base of vacuum pumps and other vacuum products. Note that we manufacture and install vacuum system automation packages for optimized delivery of vacuum and vacuum system data collection.

VMax Oil-Sealed Liquid Ring Vacuum Pumps

- 35 ACFM to 5,400 ACFM.

- Applications in Every Industrial Segment

- Water Sealing is Eliminated – Fast ROI

- Simple, Compact Design, Small Footprint

- Intelligent Electronic Controls

- Energy Efficient Design

- Variable Speed Drive Option

- 3-Year Package Warranty – Best in Industry

- 10,000-hour Vmaxol Factory Fill Lubricant

- DX-5 and DX-7 Air/Oil Separator Elements

- Quiet Operation – As Low as 70 dBA

- Options include: Specialty Inlet Filters, Multiple Pump Controls/Automation and Application Specific Accessories.

- More Information

Compact Rotary Vane Vacuum Pumps

- 2.6 ACFM to 710 ACFM.

- 0.2 Horsepower to 30 Horsepower

- Applications in Every Industrial Segment

- Simple, Compact Design, Small Footprint

- High Tech Vane Material for Long Life

- Gas Ballast Valve is Included on Every Pump

- Energy Efficient Design

- High Vacuum Models Available – 0.038 Torr Base Pressure

- Wet Service Models for High Humidity Applications

- Integral Exhaust Filter to Remove 99.9% of Discharge Oil

- Quiet Operation – As Low as 60 dBA

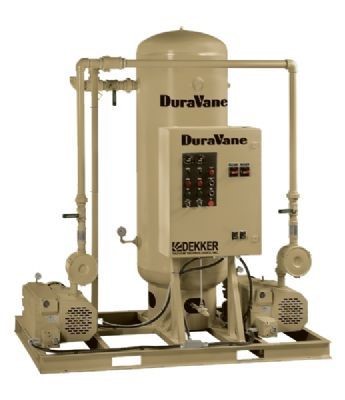

- DuraVane Dry Vacuum Pumps and Compressors Available

- More Information

Titan Series Water-Sealed Liquid Ring Pumps

Single Stage

- 6 ACFM to 1,200 ACFM.

- 0.75 Horsepower to 100 Horsepower

- Variable Discharge Port Design

- Apply to Systems Up to 29” HgV

- No Metal to Metal Contact

- Bearings External to Pumping Chamber

Two Stage

- 15 ACFM to 1,000 ACFM

- 2 Horsepower to 100 Horsepower

- Variable Discharge Port Design

- Apply to Systems Up to 29” HgV

- No Metal to Metal Contact

- Bearings External to Pumping Chamber

- Variety of Materials of Construction to Meet Application Requirements

- More Information

HullVac Series High Vacuum Pumps

Single Stage Rotary Piston Vacuum Pumps

- 52 ACFM to 850 ACFM.

- 3 Horsepower to 40 Horsepower

- 0.045 Torr Base Pressure

- Robust Design for Demanding Applications: Autoclaves, Freeze Drying, Engine Testing, Heat Treating, Thermoforming, etc.

Two Stage Rotary Piston Vacuum Pumps

- 32 ACFM to 340 ACFM

- 3 Horsepower to 20 Horsepower

- 0.0075 Torr Base Pressure

- Improved Shaft and O-ring Sealing

- Robust Valve Wear Plates

- Improved Exhaust Valve Design

- More Information