All over the world, businesses and individuals alike partake in kicking off a new year by setting new personal goals. These goals often revolve around the worthy endeavors of achieving overall wellness or reaching financial milestones.

But what about energy goals? Yeah, it’d be nice to have energy abounding without needing an espresso pick-me-up.

But we’re talking about setting a compressed air energy resolution.

If you’ve never considered your compressed air energy goals before, that’s alright. We’re here to point you in the right direction and we have just the guide for you.

REFLECTION: Be realistic about your energy needs.

In order to set realistic energy goals, you first need to assess your needs. This will require you to look at your output history and future plans, as well as your applications.

In order to set realistic energy goals, you first need to assess your needs. This will require you to look at your output history and future plans, as well as your applications.

- Are your expenses trending upward with no notable increase in output?

- Is your current compressed air system showing signs of falling behind?

Not sure? Here’s how you can tell:

- Increased need for maintenance

- Declining production

- Increased need for backup compressor availability

- Frequent part replacement

- Higher energy costs due to poor compressed air system efficiency

These types of trends can be indicators that you’re throwing money to the wind and that your compressed air system is working against your energy goals.

MAINTENANCE: Include maintenance as part of your daily routine

You can’t achieve goals without consistency; this rule applies to energy efficiency in the same way that running a marathon requires running individual miles.

If you don’t have a formal maintenance schedule now, including one in your energy resolution planning is an excellent time to start one.

Here are things for you to include in your regular compressed air routine:

Daily:

- Check drains

- Check compressor temperature

- Look for oil leaks

Monthly:

Monthly:

- Make sure the coolers are clean

Quarterly:

- Change filters

- Take oil sample

Yearly:

- Change your separator

- Replace lubricant

- Change in-line filters

EVALUATE YOUR COMSUMABLE PARTS

Lubricant choice alone can affect the life of your compressor by years. Throw in other puzzle pieces like filters, air oil separators, and air oil filters, and we’re talking about the potential of a catastrophic waste of energy.

To optimize your energy goal, check out this article on lubricant options or see this post to learn more about compressed air condensate.

CHECK FOR LEAKS: a single quarter-inch leak in your compressed air system could cost you $10,000 per year if running 24/7.

Did that get your attention? Many facilities who don’t have a regular maintenance schedule may not catch such a small leak in their system. Worse, some individuals may intentionally overlook leaks in their system by thinking it’s not a big deal.

Unfortunately, small leaks are big energy wastes and not something you want to procrastinate on.

This check list is intended to help you set reasonable energy saving goals for your facility. If you want a serious overhaul on your energy expenses, start with contacting Blake & Pendleton for a free walk through assessment with one of our professionals.

During your walk through, we look for obvious wastes of energy and indicators of subtle energy loss as well.

During your walk through, we look for obvious wastes of energy and indicators of subtle energy loss as well.

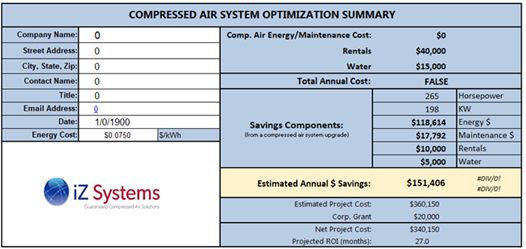

While we may make recommendations during your free walk through, we always encourage an in-depth assessment or compressed air audit for facilities who have clear need for an energy overhaul.

If you’d like to have a compressed air walk through with one of our team members or get more information on compressed air audits, reach out to us via our contact page or by calling your nearest Blake & Pendleton location.