If you’ve been searching the web for information on food grade lubricants, you may have ended up more confused on their requirements than when you started.

Indeed, there are thousands of search results that claim to have the answers, but many of them contradict themselves and one another.

To dispel some of the confusion, we are going to touch on the main features of food grade lubricants and how it pertains to your compressed air system.

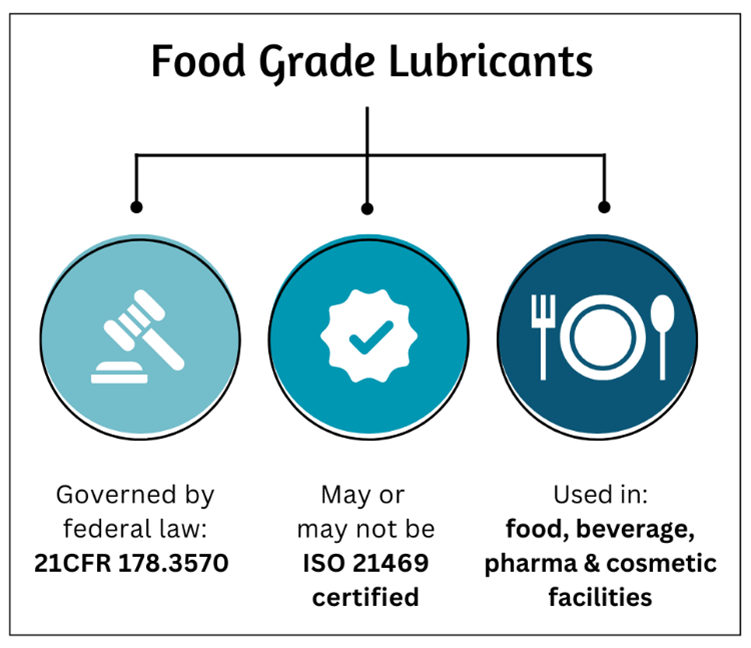

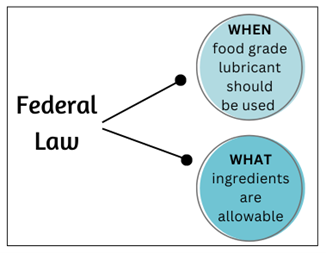

1) Defined by Federal Law

FDA Title 21 CFR 178.3570 outlines the when and what of food grade lubricants; meaning that it specifies when the use of food grade lubricant is legally required and what ingredients are allowable in the formulation of a food grade lubricant.

WHEN

WHEN

When the lubricant has any chance of incidental contact with consumable food product, a food grade lubricant must be used.

This includes lubricants throughout a facility that may incidentally contaminate the machinery that comes into contact with the consumable product.

WHAT

In the interest of public safety, the FDA regulates ingredients that are approved in the formulation of a food grade lubricant.

Not every ingredient is required to be in a single food grade lubricant so you will still find a variety of formulations on the market.

While we won’t go over the list in this article, you can check out the FDA’s list of approved ingredients here for further research.

SIDE NOTE —> HOW MUCH

If you observe the FDA’s list of approved ingredients, you may notice that some ingredients have limitations on how much is allowable in the lubricant formulation.

Keeping with toxicity standards, some ingredients are safer at lower levels.

2) May or may not be ISO 21469 certified

In the US, ISO 21469 certification through the NSF is voluntary.

We want to highlight this point because this is where the line gets hazy if you’ve been searching the web for food grade lubricants and their requirements.

We know what you’re thinking: Why would companies get certified if it’s not required?

The NSF is a third-party company who will audit lubricant manufacturers upon their request and certify that their product and procedure adheres to FDA standards in addition to their own stringent standards for quality and product safety.

The NSF is a third-party company who will audit lubricant manufacturers upon their request and certify that their product and procedure adheres to FDA standards in addition to their own stringent standards for quality and product safety.

In other words, obtaining ISO 21469 certification from the NSF:

- Affirms quality of product

- Assures quality of manufacturing procedure

- Bolsters positive company reputation

Considering the benefits of NSF ISO 21469 certification, it’s no wonder that facilities will go out of their way to obtain it.

Considering the benefits of NSF ISO 21469 certification, it’s no wonder that facilities will go out of their way to obtain it.

Similarly, NSF Registration shows that a product and its ingredients have been closely reviewed by the NSF and that it does meet the FDA requirements and NSF H1 standards.

So, while it is not required, our professionals at Blake & Pendleton highly recommend going with an NSF Registered or Certified Food Grade Lubricant when given the option.

We recommend Sullair’s Pristine FG Compressed Air Fluid, which has been H1 Registered with the NSF since 2011. View Sullair’s official letter of registration here.

3) Industries that use food grade lubricants

While “food” in the name may denote a sense of a single-industry use, food grade lubricants can be used in any facility that manufactures consumable product. Food, beverage, pharmaceutical, and cosmetic industries are the most common consumers of food grade lubricants.

A word of caution, pharmaceutical facilities have safety and construction guidelines that provide more specific direction of lubricant use. Always make sure that you are following your sector’s governing regulations.

Food grade lubricants for your compressed air system

Most air compressors and their related parts don’t come into direct contact with a food product.

But in some circumstances, the compressed air downstream may come into contact with the product or with other machinery that interacts with food product.

It’s important to be aware that “incidental food contact” may happen in a number of ways and your compressed air system could be in the lineup of indirect offenders.

As required by most food and like facilities, regularly testing your product and being aware of all contributing players is the best way to ensure product safety.

If you’re in the market for a compressed air food grade lubricant, reach out to our team. We’d love to discuss your needs and compressed air system modifications that can be made to help you meet your production goals.