AirSequal compressor automation reaches new heights in automation capabilities and redefines what energy efficiency looks like.

Using standard Allen Bradley hardware, AirSequal achieves optimum productivity at an ROI that makes it affordable for every facility.

Lead Compressor Rotation

Checking all the boxes in compressor scheduling, AirSequal allows you to create a compressor rotation based on your facility’s fluctuating air demand; want to schedule the rotation based on certain times of day? Check. Schedule differently for weekdays and weekends? Check.

While other automation systems allow for lead compressor rotation, AirSequal separates itself from competitors with a unique and innovative technology: rate-of-change monitoring.

AirSequal’s Rate-of-Change Software

Exclusively available in AirSequal, the rate-of-change (ROC) software monitors compressor pressures and also the speed at which these pressures are changing. Pressure monitoring allows the software to make accurate predictions to decide when or if it should bring more compressors online. Also working in reverse, AirSequal’s ROC software analyzes when it should take compressors offline.

Exclusively available in AirSequal, the rate-of-change (ROC) software monitors compressor pressures and also the speed at which these pressures are changing. Pressure monitoring allows the software to make accurate predictions to decide when or if it should bring more compressors online. Also working in reverse, AirSequal’s ROC software analyzes when it should take compressors offline.

The exclusive capability of ROC monitoring enables your compressors to work together towards the same goal: an efficient, reliable and steady flow of air that is custom-designed to meet your production needs.

From Wasted Energy to Saving Money

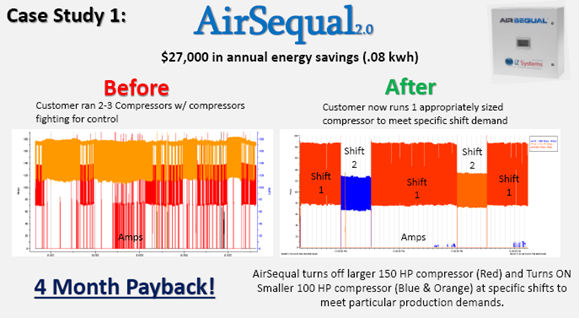

Imagine this: a facility constantly runs 2-3 air compressors around the clock; starting and stopping compressors haphazardly in an attempt to keep a steady air flow. Sound familiar? That’s because it’s a common issue in facilities operating multiple compressors. And it’s exactly one of the issues that AirSequal automation corrects.

Check out this AirSequal case study:

By adding AirSequal automation to their existing compressor line up, this facility was able to accomplish smooth transitions and reliable air output; all while saving tens of thousands of dollars per year. That’s a massive turnaround!

While AirSequal’s abilities are unique, the energy savings provided by this automation system isn’t. 35% of energy savings is a common outcome for facilities that introduce AirSequal to their current compressor set up.

Additional AirSequal features include:

- Controls up to 6 rotary screw compressors

- Uses standard Allen Bradley plc hardware

- One screen to view the status of all compressors

- Remotely view reports from cell phone or computer

- Menu uses common and industry standard terminology

To learn more about AirSequal and their unique automation capabilities, contact Blake & Pendleton today!